Superior Seals | Exceptional Service

Premier Manufacturer and Distributor of Seals & Gaskets

Superior Seals

Exceptional Service

WE ARE ISO9001:2015 & AS9100D CERTIFIED.

Industries

Industrial

Industries

Communication & IT

Industries

Military

Industries

Aerospace

Industries

Fluid Power

O-Rings

O-rings from Parker’s O-ring and Engineered Seals Division are available in both standard and metric sizes.

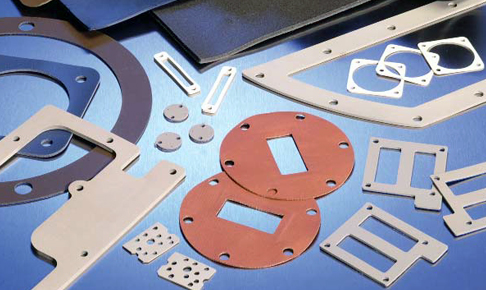

Gaskets

Die-cut gaskets and industrial gaskets are available for needs of temperature, chemical compatibility, pressure and more.

Molded Rubber Parts

Custom molded rubber parts made in the US have several advantages and are available for compression, transfer, and injection molding.

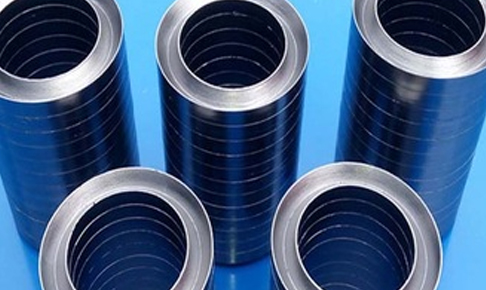

EMI Shielding

We offer EMI shielding O-rings and EMI conductive gaskets for ruggedized and outdoor EMI applications.

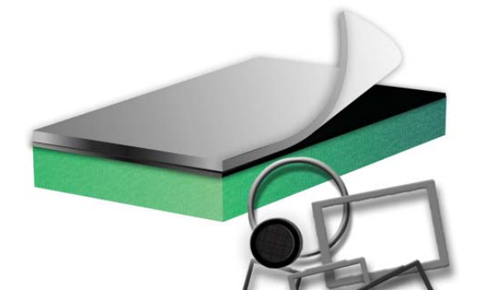

Thermal Management

We provide Thermal Interface Materials from Parker Chomerics. These materials have been designed into many applications.

GORE Vents

GORE vents let sealed enclosures breathe, allowing airflow in and out, and improve enclosure failed seals performance.

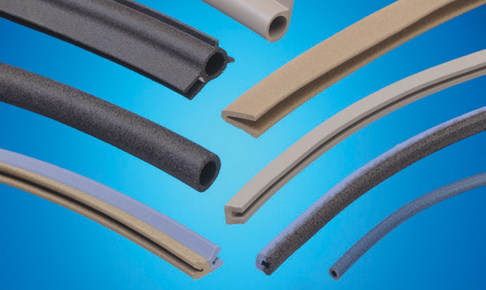

Sponge Cellular Foams

When designed for the application, sponge is an ideal solution for sealing out harsh environmental elements to help engineers meet IP specs.

Adhesives & Sealants

We offer pressure-sensitive adhesives (PSA’s), tapes, threadlockers, epoxies, sealants, and one or multi-part sealants.

Latest Post

Radome Sealing and Venting Solutions for Electronic Enclosure Protection Case Study

Customer Overview Sealing Devices’ customer provides essential satellite communications systems to many leading government and military agencies and defense contractors.The customer needed help designing an antenna radome to allow for communication, navigation, and...

Compressed Fiber Sheet Gaskets

Transition from Asbestos to Safer Materials Asbestos, once widely used in gaskets, was phased out due to recognized health hazards, leading to a need for safer alternatives. Companies like Garlock, Klinger, and Armstrong responded by developing asbestos-free materials...

O-Ring Considerations

O-rings are circular sealing devices with a round cross-sectional profile, usually made from rubber compounds (or elastomers). They are simple, easily replaceable, and can be highly economical, which has helped them remain in use for hundreds of years and spread to...

About Us

It all started with an investment of $157

July 1966

Sealing Devices moved to an old battery manufacturing plant on Neoga Street in Depew, NY to keep up with the expanding business.

July 1963

Terry Galanis, Sr. launched Sealing Devices Inc. from his Alden, NY home