EMI Shielding

RFI and EMI Shielding Material

Sealing Devices is a leading distributor and fabricator of EMI (Electromagnetic Interference) / RFI (Radio Frequency Interference) shielding products.

Sealing Devices converts and distributes a wide range of EMI shielding material including conductive elastomers, conductive adhesives, vents, windows, and more. Depending on the needs for your application, you can rely on Sealing Devices applications support and engineering assistance for integrating EMI shielded products into your solution.

Our Trusted Suppliers

We partner with Parker Chomerics and other leading suppliers to provide premium EMI shielding materials to a wide range of industries ensuring high-performance and quality for thousands of applications.

What Is EMI Shielding?

EMI, or electromagnetic interference shielding, is the practice of blocking electromagnetic interference, preventing it from damaging sensitive electronic devices. Sealing Devices distributes a wide range of emi shielding products, including emi shielded vents, gaskets, and windows.

The purpose of EMI shielding is to create a barrier that prevents leakage of strong electromagnetic fields that can interfere with sensitive devices and signals. Electromagnetic Interference (EMI) can cause minor to major disruptions and malfunctions to electronic devices, equipment and many other systems that are used in critical applications. To list a few military, aerospace electronics, mass transit systems, industrial touch screens, navigation, and vehicular control systems.

Common EMI Configurations

- EMI Shielded Gaskets (Elastomer, Copper, Metal, Mesh, and more)

- EMI Shielded windows

- EMI Shielded adhesives

- EMI Shielded vents for ventilation and moisture draining

EMI Shielding Products

Conductive Elastomers

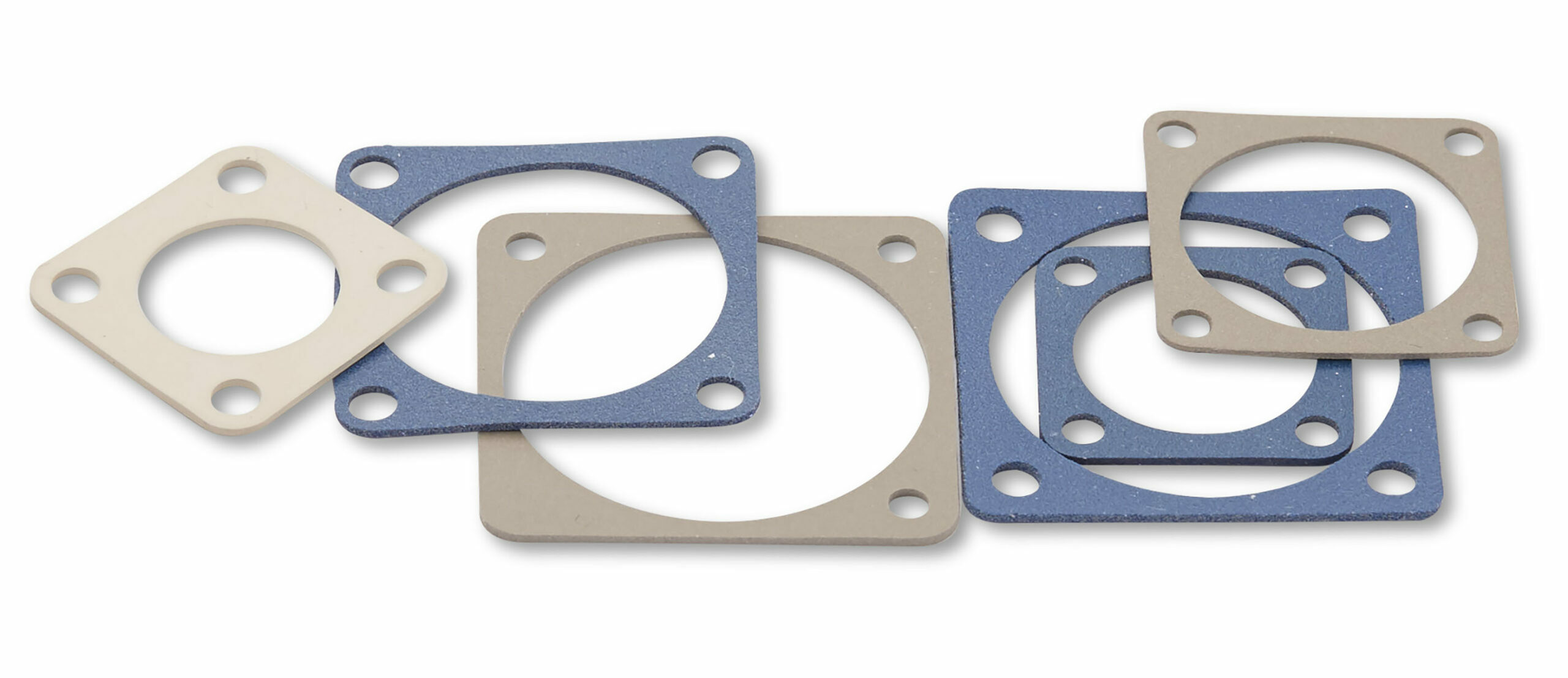

Parker Chomerics electrically conductive elastomer gaskets are the superior choice for corrosion resistance, environmental sealing, and cost-effective EMI shielding.

Form-in-Place EMI Gaskets

Sealing Devices is an in-house dispenser of form-in-place gaskets using Parker Chomerics CHOFORM® Form-in-Place EMI gasket compounds.

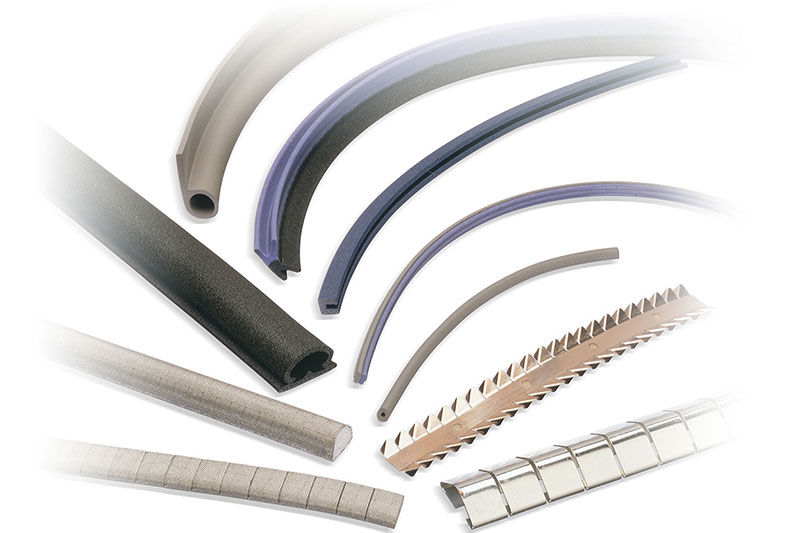

Copper & Metal Mesh Gaskets

SPRING-LINE™ gaskets are highly resilient, highly conductive, knitted wire mesh strips used to provide electromagnetic interference (EMI) shielding and electromagnetic pulse (EMP) shielding at the joints and seams of a variety of enclosure applications.

EMI Shielded Vents

Chomerics STREAMSHIELD™ vent panels provide high performance, economical solutions to EMI shielding and airflow issues in electronics and telecommunications applications.

EMI Shielded Windows

Sealing Devices provides performance-tested EMI shielding windows for visual displays. The custom sized selections are available in glass and plastic.

Conductive Adhesives

Electrically conductive adhesives from Parker Chomerics are primarily used for electronics applications where components need to be held in place and an electrical current can be passed between them.

Low Compression Force Gaskets

Parker Chomerics family of SOFT-SHIELD fabric-over-foam electromagnetic interference (EMI) shielding gaskets provide an EMI gasket solution suitable for most all indoor EMI shielding and grounding applications requiring low compression force.

Connector Gaskets

Parker Chomerics connector gaskets are die-cut from premium sheet materials to provide effective EMI shielding and pressure sealing in standard and custom connector applications.

Why Is EMI Shielding Important?

EVALUATING EMI SHIELDING GASKETS AND EMI O-RING EFFECTIVENESS

Choose EMI shielding O-rings based on the radiated emission spectrum of your equipment and the specifications each unit must meet. EMI O-ring and EMI gaskets provide different levels of EMI shielding effectiveness across a frequency range of 10 kHz to 20 GHz.

EMI OPERATING CONDITIONS

Many EMI O-rings and EMI conductive gaskets provide a ‘best fit’ for different operating environmental conditions, including exposure to high and low temperatures, wind and rain, salt spray, solvents and other conditions that can affect the life of EMI shielded gaskets and EMI shielded O-rings. Read about how we addressed environmental & installation challenges in this case study.

EMI MECHANICAL REQUIREMENTS

The primary goal of an EMI shielded gasket is to seal an electronic enclosure to prevent transmission of electromagnetic interference. Improper design of an EMI seal or enclosure flanges can result in failure. Mechanical design issues must be considered for the proper mating of an EMI gasket with the flanges of an electronic enclosure based on EMI conductive shielding theory.

COMPRESSION-DEFLECTION

EMI shielded gaskets require varying compressive force depending on the seal solution. Conductive fabric over foam solutions offer high shielding with low compressive force. Conductive filled elastomer gaskets and seals require slightly higher compressive load. The advantage is conductive filled elastomers can also be used for environmental sealing in addition to EMI shielding.

COMPRESSION SET

EMI shielded gaskets subjected to compressive forces over extended time causes ‘deflection’ to remain after the load is removed. EMI gasket compression set is an important property when an EMI gasket will be compressed and released regularly in enclosure door and access panel service.

ELECTRICAL STABILITY

EMI gaskets and EMI O-rings provide conductive pathways that electrically bond components to a common ground. EMI shielded gaskets serve as low impedance conductors to improve enclosure reliability.

INSTALLED COST

EMI gasket installation is a major factor in determining costs. EMI Shielded gaskets can be installed using PSA’s, fasteners, epoxies, or press-fitting into grooves. EMI gaskets can be molded in place on the enclosure flange or plastic spacer frame.

Why Choose Sealing Devices For EMI Shielding?

High-Performance Products: Our EMI shielding solutions are designed to provide effective protection against electromagnetic interference, ensuring the reliability and performance of your electronic devices.

Expert Engineering Assistance: Our application engineers have years of expertise and are ready to assist you with your EMI Shielding installation. Our engineers provide services such as design assistance, material testing, failure analysis, and more.

Advanced Manufacturing Capabilities: Our state-of-the-art manufacturing facility and in-house tooling and die-making capabilities allow us to quickly produce and distribute custom EMI shielding products.

EMI Shielding Applications

EMI Shields are used across numerous industries, such as aerospace, military, and electronics, to protect sensitive electronic equipment from harmful EMI exposure. View all of our EMI Shield offerings to find the type that best fits your specific application.