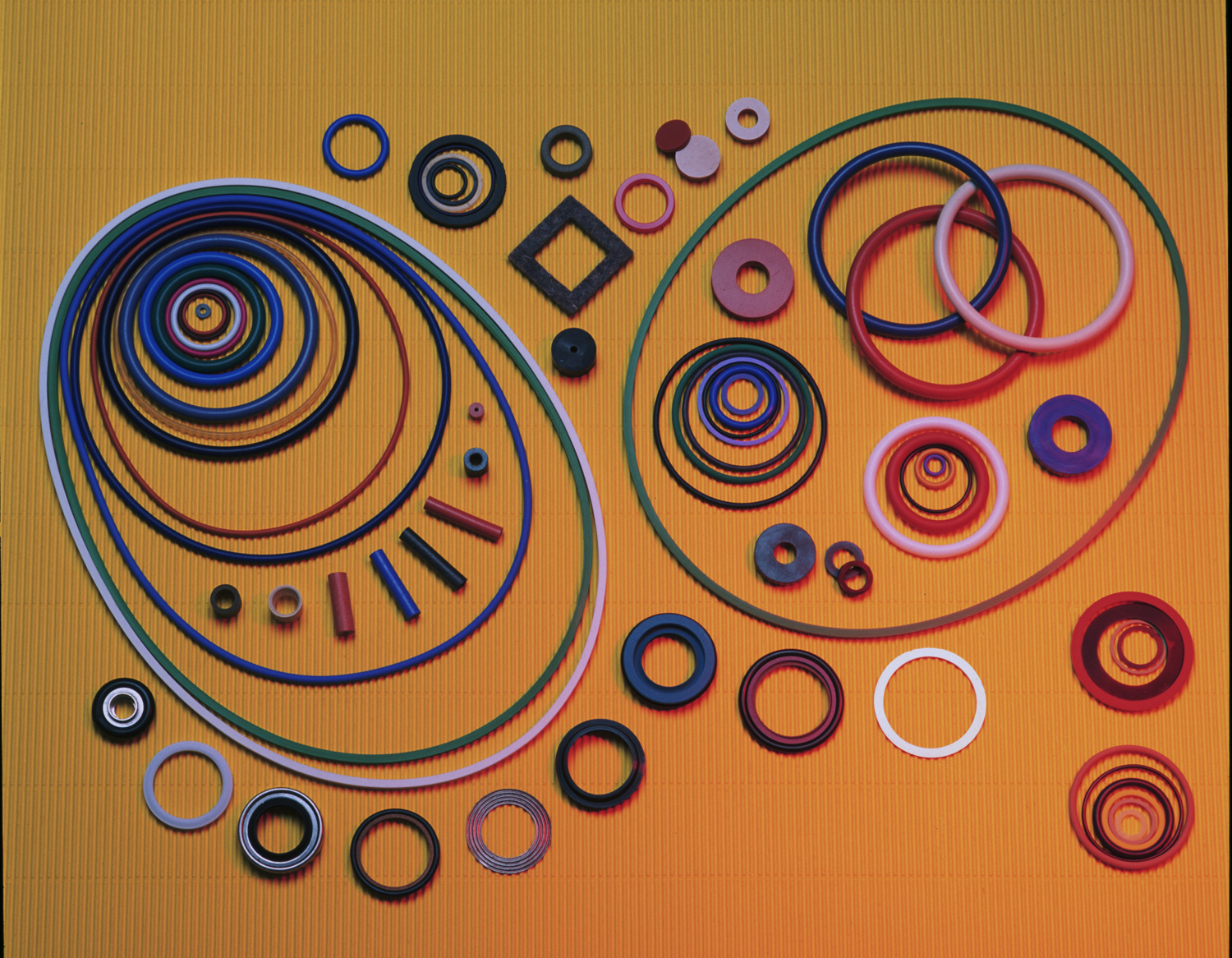

O-Rings

Industry-Leading O-Ring Distributor

Sealing Devices is North America’s premier o-ring manufacturer and distributor, offering an extensive range of o-rings. From silicone to FFKM o-rings, our products are designed to cater to both standard and complex applications. With thousands of products to choose from our top suppliers such as Parker o-rings, our team of application engineers can help you determine the right product for the job.

Our Trusted Suppliers

We collaborate with leading suppliers such as Parker, Freudenberg, Kalrez, and moreensuring access to reliable and high-quality O-ring products tailored to your specific application needs.

What is an O-Ring?

An O-ring is a circular, or doughnut-shaped sealing device, generally molded from an elastomer or thermoplastic material, such as PTFE. O-rings engineered to fit snug into grooves and compress between two or more parts to form a seal. O-rings are used primarily for sealing and protecting against liquid and gas loss, and can function in a wide range of temperatures and pressures.

What is an O-Ring Seal?

An O-ring is a circular cross-section ring molded from polymer, and is used to prevent the leakage of a liquid or gas. The seal assembly generally consists of an elastomer O-ring which sits in a sealing gland. The gland — usually cut into the metal or other rigid material of the fluid system — contains and supports the O-ring. Each of these two elements is meticulously designed and manufactured to create the best possible seal.

What are the Advantages of O-Rings?

- Wide Range of Sealing Capabilities – O-rings can seal across a wide range of pressures, temperatures, media, and geometries.

- Low Maintenance – O-rings offer ease of service, requiring zero amount of smearing or re-tightening.

- No Tightening Required – No critical torque on tightening, making them unlikely to cause structural damage.

- Lightweight & Compact Design – O-rings are lightweight and take up minimal space, making them great for applications where a compact sealing solution is needed.

- Cost Efficiency – As o-rings are inexpensive to install, they are a cost-effective sealing choice for many applications.

- Reusability – They can often be reused, unlike non-elastic flat seals and crush-type gaskets.

- Long Lifespan – When used properly, the lifespan of an o-ring will match the normal aging period of the specific o-ring material.

- Failure Detection – O-rings typically fail in a gradual manner, making it easy to identify and address potential issues.

- Less Sensitive to Compression – Since an o-ring groove generally allows for metal-to-metal contact, they are not affected by differing amounts of compression, such as with flat gaskets.

How Are O-rings Sizes Measured?

O-rings are measured by their internal diameter (ID), outer diameter (OD), and cross-sectional diameter (CS). These measurements are taken in inches or millimeters and are important for ensuring a correct fit and proper seal. Sealing Devices carries multiple o-ring styles including AS568, the SAE standard. Refer to our o-ring size chart to assist you in finding the right fit.

O-Ring Products

FFKM O-Rings

Perfluoroelastomer (FFKM; Kalrez) O-rings offer resistance to the highest temperatures of any rubber, coupled with extremely broad chemical compatibility and very low extractable levels.

FKM Viton O-Rings

Fluorocarbon (FKM; Viton) O-Rings offer excellent resistance to high temperatures, ozone, oxygen, mineral oil, synthetic hydraulic fluids, and many other solvents and chemicals.

FVMQ O-Rings

Fluorosilicone (FVMQ) O-Rings are a hybrid of silicone and FKM, creating a good general purpose seal for aerospace and jet fuel applications.

AFLAS O-Rings

AFLAS O-Rings are resistant to a wide range of chemicals, making them ideal for engine coolants and automotive fluids.

Buna-N Nitrile O-Rings

Buna-N (NBR; Nitrile) O-Rings offer excellent sealing and mechanical properties at a low cost. Great for general purpose sealing.

EPDM O-Rings

EPDM O-rings provide resistance to heat, water, steam, ozone, and sunlight.

Neoprene O-Rings

Neoprene (CR; Chloroprene) O-Rings provide good resistance for UV, oxygen, and weather applications.

Silicone O-Rings

Silicone (VMQ) O-Rings provide good insulating properties, as well as sealability at high temperatures. Available in all standard sizes.

Custom O-Rings

No matter the application, we can customize a solution that will fit your needs.

Why Choose Sealing Devices for O-Rings?

Commitment To Quality: We follow rigorous quality control processes and adhere to industry standards to provide reliable and durable O-ring sealing solutions. Our ISO 9001:2015 and AS9100D certifications reflect our commitment to excellence.

Unmatched Supplier Partnerships: Proudly aligned with some of the largest seal manufacturers in the world to provide the most reliable and advanced sealing solutions to meet the diverse needs of our customers.

Wide Range of Materials: Sealing Devices offers o-rings made out of an array of materials. From silicone to neoprene, our o-rings are designed to withstand various applications and environments.

Expert Guidance and Support: Our engineers provide comprehensive support from design assistance to material selection and troubleshooting. They ensure you find the right O-ring solution for your specific needs, backed by years of sealing expertise.

Ease of Sizing and Selection: With a clear sizing guide including AS568 standards, our O-ring size chart assists in selecting the correct fit for your application, ensuring proper sealing effectiveness.

Speak With Our O-ring Experts

Sealing Devices specializes in o-ring products that can be used across a wide range of industries, including aerospace, electronics, military, and more.

If you’re unsure what o-ring product is best for your specific application, our skilled Applications Engineers are here to help with design assistance, material testing, and more to ensure you find the right solution.

When you work with Sealing Devices, you are working with a dedicated team of experts with years of sealing knowledge and expertise.